Home >> Research Article

Article

58042I – A Design of Lathe Boring Tool with Rotating Cutter Principle

Created by : , Publish 09 Feb 2016 , Views 543

[ คัดลอกลิ้งค์ ] [ แชร์ให้ผู้อื่น ]

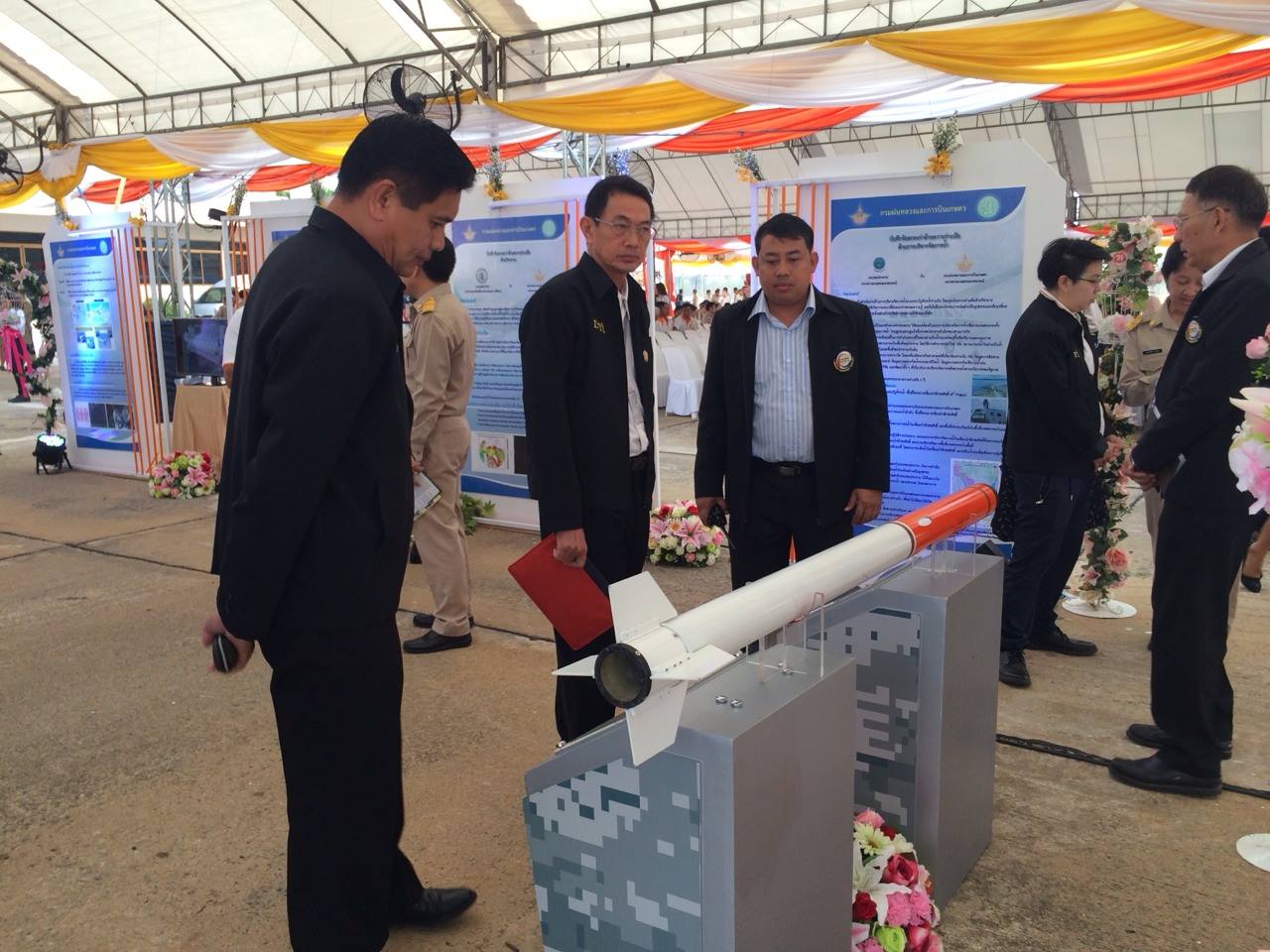

| view Abstract and Download Abstract : Boring process is the machining process to enlarge an internal diameter of cylindrical tubes and is considered one of the most important processes in rocket motor manufacturing. In general, vertical boring is used over horizontal boring in order to control dimensional accuracy and concentric of bored tubes. However, vertical boring process required a specific machine which can be a burden to manufacturer. In this study, the lathe boring tool is developed to reduce the cost of acquiring new machine. In a typical boring process using horizontal lathe, the ratio between workpiece internal diameter and length is restricted to 1:3. If the length is too long, defects such as uneven roughness can be observed due to vibration of cutting insert. The new horizontal boring tool is designed based on rotating cutter principle. The designed is simulated using finite element method and tested on S40C cylindrical tubes. The surface finished of tested workpiece is within tolerance and acceptable.

|

Defence Technology Institute

Office of the Permanent Secretary of Defence (Chaengwattana) 5th Floor, 47/433 Moo 3, Ban Mai, Pak Kret, Nonthaburi 11120 Tel: 0 2980 6688 , Fax: 0 2980 6199

Office of the Permanent Secretary of Defence (Chaengwattana) 5th Floor, 47/433 Moo 3, Ban Mai, Pak Kret, Nonthaburi 11120 Tel: 0 2980 6688 , Fax: 0 2980 6199

Copyright © 2025 Defence Technology Institute. All Rights Reserved.